Supplies Needed to Complete this Task

For your custom foam cushions, you will need a sheet of foam, your modified cushion measurements made during the How to Measure step, a tape measure, a long straight edge like a yard stick and a sharp carving knife or electric knife to cut your foam. The blade of your cutting tool must be longer than the foam’s thickness to allow you to cut through completely.

Plotting Your Cushions

Using the adjusted measurements you recorded during the How to Measure step, plot out the dimensions of a square or rectangle that represents the greatest length and width of the custom cushion. This is most easily done by cutting out the shapes from old newspaper. Placing these rough templates on the sheet will give you an idea of how closely you need to plot your cushions on the foam, as well as ensuring that you orient the foam in such a way that you won’t run out of material on your final cushion. Three cushions may fit side by side on foam horizontally but may not fit stacked on top of each other in a vertical layout. With these in place, make small tick marks on the edge of the foam to mark the boundary area for each cushion.

Marking the Foam - Part One

Using the adjusted measurements you created during the How to Measure step, begin to mark the shape of your foam within its designated boundary area. Whenever possible, use the outside edge of the foam sheet as an edge for your cushion to reduce the number of cuts you must make. For square or rectangular cushions, creating your design in the corner of a sheet means there are already two sides cut for you. However, do not lay out a design that requires any of your new cushions to share a cutting edge. A single mistake can ruin two cushions with this layout, while having room around each form can make a slip-up manageable.

Using the adjusted measurements you created during the How to Measure step, begin to mark the shape of your foam within its designated boundary area. Whenever possible, use the outside edge of the foam sheet as an edge for your cushion to reduce the number of cuts you must make. For square or rectangular cushions, creating your design in the corner of a sheet means there are already two sides cut for you. However, do not lay out a design that requires any of your new cushions to share a cutting edge. A single mistake can ruin two cushions with this layout, while having room around each form can make a slip-up manageable.

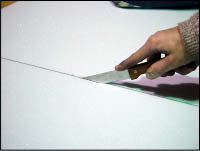

Using the edge of the foam facing you as the back edge of the cushion, begin marking the foam using a straight edge, as seen to the right. Make periodic tick marks with a marker, spread apart at a distance you are comfortable with. Do not draw lines just yet, in case a measurement error was made.

Marking the Foam - Part Two

Double check to be sure your measurements are straight and correct and that they fall within the cushion's boundary area. When this is confirmed, use the straight edge and marker to connect the dots. Take care not to tear into the foam with the marker tip. These are the guidelines you will follow as you cut out your cushion.

Double check to be sure your measurements are straight and correct and that they fall within the cushion's boundary area. When this is confirmed, use the straight edge and marker to connect the dots. Take care not to tear into the foam with the marker tip. These are the guidelines you will follow as you cut out your cushion.

Cutting the Foam

Before beginning to cut the foam, be sure your work surface is stable, flat and will not be damaged by the knife. If you are using a carving knife, use a gentle back-and-forth sawing motion and let the blade do the cutting. Do not compress the foam and attempt to slice through quickly. The less the foam is compressed during cutting, the more control the user has over maintaining a flush edge. Cut it as if you were slicing freshly-baked bread. The picture to the right depicts the ease with which a sharp blade can cut foam without compression. If you use an electric knife, do not force the blade through the foam. The slower you cut, the more control you have and the cleaner the cut will be. Whenever possible, begin cuts from the sheet's outside edge.

Before beginning to cut the foam, be sure your work surface is stable, flat and will not be damaged by the knife. If you are using a carving knife, use a gentle back-and-forth sawing motion and let the blade do the cutting. Do not compress the foam and attempt to slice through quickly. The less the foam is compressed during cutting, the more control the user has over maintaining a flush edge. Cut it as if you were slicing freshly-baked bread. The picture to the right depicts the ease with which a sharp blade can cut foam without compression. If you use an electric knife, do not force the blade through the foam. The slower you cut, the more control you have and the cleaner the cut will be. Whenever possible, begin cuts from the sheet's outside edge.

IMPORTANT: Softer foams, like for futons, compress more easily during cutting. Taking caution to minimize pressure while cutting will result in cleaner edges. Medium and firm foams, like used in a boat mattress, will hold their shape better during cutting, but do not use this as a reason to apply extra force.

Previous: How to Measure Your Cushion

To adhere two pieces of foam to create your cushion, go to How to Glue Foam Together

To wrap the foam in polyester fiberfill, go to How to Apply Fiberfill Wrap to Your Cushion

To use a foam-only form for your cushion, skip ahead to How to Stuff Your Cushion

How-To's

IMPORTANT: Always be careful when handling sharp objects and use safety glasses. We are not responsible for any harm, damages and / or losses caused when using these or any other potentiality harmful objects when working on your projects.